REQUEST ADVICE CONVERSATION

We are happy to advise you how to solve odour and emission problems. We strive to find the best sustainable solution. As every question is different, we would like to have personal contact with you, so we can go through all the details carefully.

Enter your details and one of our odour experts will contact you to make an appointment:

Product: Wet scrubber Branche: Odorants and flavourings, Food

Odour nuisance due to the addition of odorants and flavourings

Client request

During the production process of breakfast cereals fragrances and flavours are added for better taste. These additives are also partially in the air flow which leaves the building. Furthermore the air flow contains residues from vegetable oils. The production site is located near the centre of a large European city. Both the odour emission as the vegetable oils are a nuisance to the environment and have led to a series of complaints.

What is the most reliable technique to filter and clean the air?

solution AEC SYSTEMS

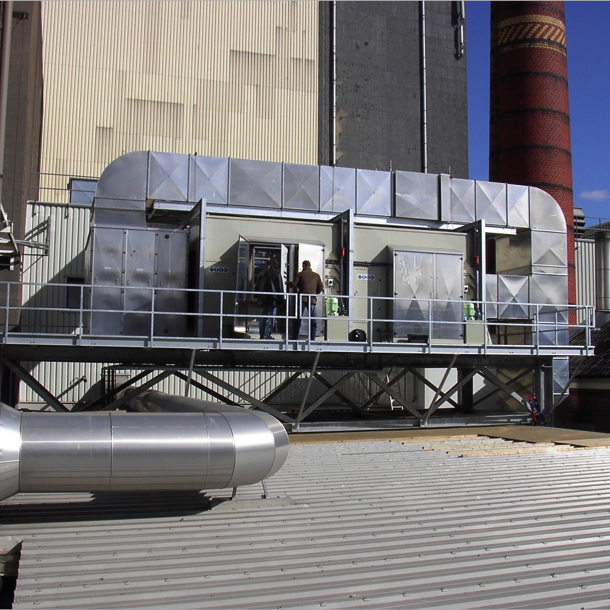

After various tests we developed a multi stage wet scrubber including pre-treatment in order to filter the air from vegetable oils. A heat exchanger takes advantage of the residual heat from the airflow to use it elsewhere in the production process. The scrubber is seamlessly integrated into the existing and unique situation of the production site.

The project contains:

- a multi stage scrubber

- a double walled storage tank

- air ducts

- an air collect room

- complet control automation (Siemens) of all components

Advantages of the AEC Multi Stage Scrubber

The water packages of the multi stage scrubber have an extra large surface and offer a low air resistance at the filter during the cleaning of the air flow.

A unique pump technology enables a continuous irrigation of the unit so that it keeps the complete system clean.

The system, like all products of AEC Systems, is easily accessible and therefore maintenance friendly. These are all advantages why the owner of the sludge treatment plant chose AEC Systems.

Technical data:

Air flow: 60.000 m3/h

Temperature: 50-70˚C